Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 17, 2007 01:06 PM

posted July 17, 2007 01:06 PM

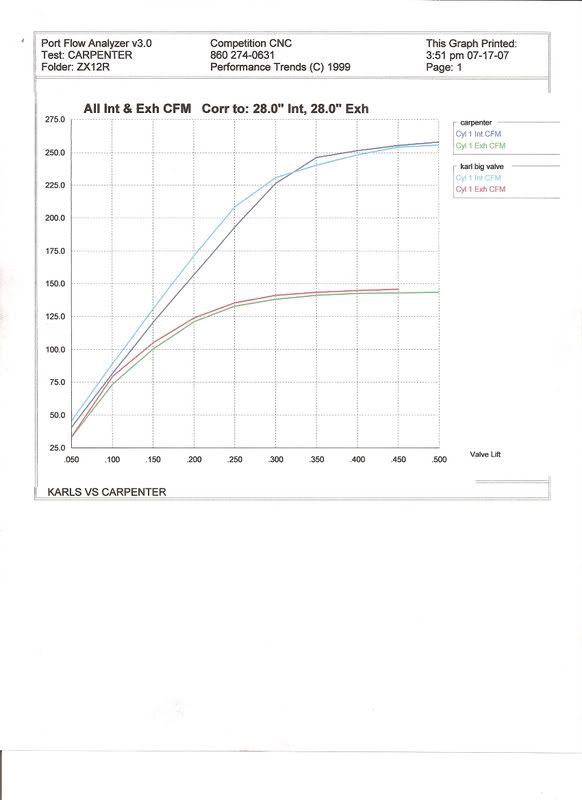

Ok, I tested the CNC ported Carpenter head. It has stock valves and no chamber work.

____________

Y2KZX12R

CompetitionCNC.com

|

Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 17, 2007 01:10 PM

posted July 17, 2007 01:10 PM

Karl, I think the lower numbers for your head @ .350" and .400" can be fixed with some chamber work. Some unshrouding where the seat cutter left a ridge, and also some unshrouding that the factory cutters were so kind to leave.

____________

Y2KZX12R

CompetitionCNC.com

|

entropy

Moderator

Posts: 8671

|

posted July 17, 2007 06:58 PM

posted July 17, 2007 06:58 PM

Jim,

it looks like my int curve is missing a data point at .350.???

Optical dillusion???

On the unshrouding, gotta be careful with the offset cylinders...

In any event, thanks a million for testing both heads and posting them We will all learn something.

Ryan beats me at everything!

His wife even has a job!

____________

This moderator uses moderation in moderation

|

MadMike

Moderator

FEAR THE BLACK FLAG!!!!!!!!

Posts: 6579

|

posted July 17, 2007 07:05 PM

posted July 17, 2007 07:05 PM

quote:

Ryan beats me at everything!

His wife even has a job!

LMAO.....

____________

200-MPH CLUB MEMBER!

|

Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 18, 2007 03:30 AM

posted July 18, 2007 03:30 AM

Edited By: Y2KZX12R on 18 Jul 2007 04:31 Edited By: Y2KZX12R on 18 Jul 2007 04:31

Mike, is that head your current head your running on the bike now? Is it on the bike?

If so next time you have it off ship it to me and i'll flow test it and we can compare all the raw dry flow numbers.

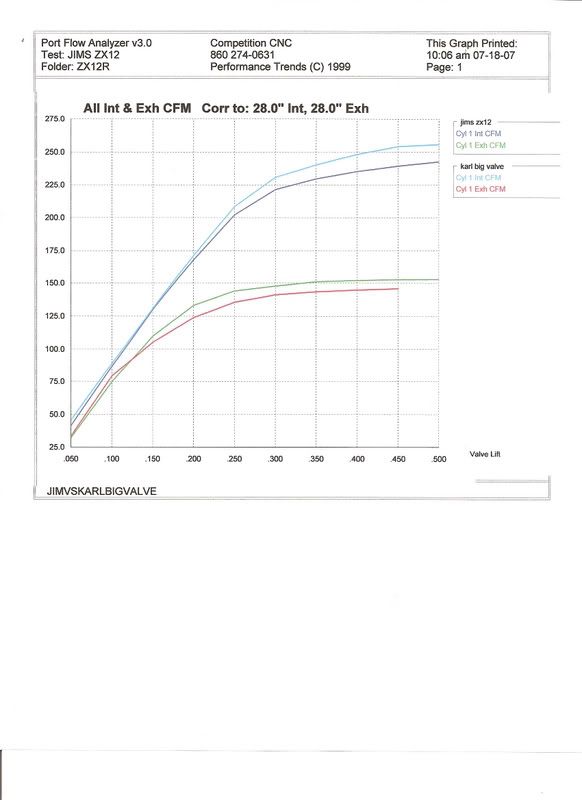

Karl, @350... its just a straight line. I wouldnt say that the carpenter head beats your big valve head. Your head flows more air all the way up to .325". Peak flow numbers arnt the most important. Remember the valve is at peak lift only once per cycle and for a very short time.

Its at .250" twice, opening and closing. And also as far as making power, flow bench numbers on a dry flow bench arnt the only numbers to look at for making power. Seat turbulance, window area, velocity, cross sectional areas, seat timings, etc. all are a big factor in making actual power.

As far as offset cylinders... It would be best to develop two diferent chambers, an inner and an outer. this way the shape is customized for the cylinder offset and the chamber isnt simply moved over. so there should be 3 chambers... a std location for std blocks and an inner and outer chamber for offset blocks.

Ryan, your BigBusa will have an offset cylinder block correct? I'll need that offset amount to shape your chambers as required for that BigBusa head coming up. That reminds me I've gotta get that plate fixture on order for the busa head. I'll be ready to work on that in august for ya.

____________

Y2KZX12R

CompetitionCNC.com

|

Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 18, 2007 06:40 AM

posted July 18, 2007 06:40 AM

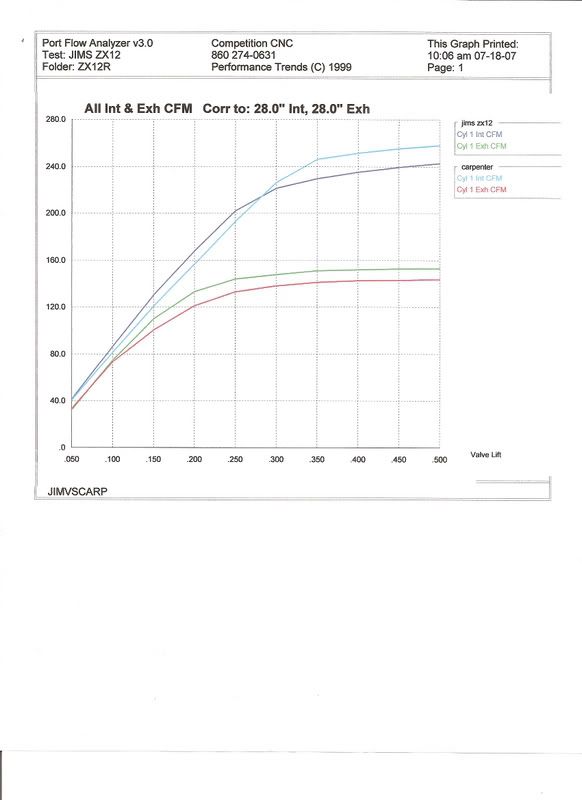

This graph is carpenters cnc ported head vs my head that I did back in 2001. my head has chamber work and some exhaust porting, and a very, very little bit of intake port work.

And this one is Karls big valve head vs my head.

One of these days I'd like to do a full cnc port and chamber for the zx12r head. If i could just survive on 1 hour of sleep everything would be soooo much easier to get done.

____________

Y2KZX12R

CompetitionCNC.com

|

entropy

Moderator

Posts: 8671

|

posted July 18, 2007 08:00 AM

posted July 18, 2007 08:00 AM

Jim,

thanks for the trouble you went to flowing and posting, flowing and posting, flowing and posting...

I know you are taking time away from yr new CNC baby to help us, so yr effrts are doubly appreciated.

I wonder what the differences in the exhaust curves are due to???

You make me feel better about ryan's peak number vs mine, and the impact of lower lift flow numbers, but i am impossibly far from understanding the impact of flow rates on hp. Maybe with time something will sink in.

____________

This moderator uses moderation in moderation

|

Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 18, 2007 08:28 AM

posted July 18, 2007 08:28 AM

No problem Karl, I love this shit as much as the next guy... actually even more!

The differences in the exhaust are from porting I did on the exhaust in 2001.

Mostly from reshaping the seats etc.

Believe it or not 1/4" above and below the 45deg. seat angle is where allmost all flow gains come from when "porting". A proper valve job is the best bang for the buck.

If you want to really know whats going on in the ports try reading some SAE papers on the subject. You will have to buy the ones you want to read but they are cheep and very thought provoking to say the least.

I cant get into all the formalities of this stuff without writing a book on here... theres a ton of SAE papers on this stuff. check out thier web site.

____________

Y2KZX12R

CompetitionCNC.com

|

supra5677

Pro

Posts: 1279

|

posted July 18, 2007 10:16 AM

posted July 18, 2007 10:16 AM

Y2K can you do anything with a stock head and an extended rev limiter with a race intake cam? stock displacement of course.. and a little added compression?

supra

|

Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 18, 2007 12:03 PM

posted July 18, 2007 12:03 PM

quote:

Y2K can you do anything with a stock head and an extended rev limiter with a race intake cam? stock displacement of course.. and a little added compression?

supra

As in a valvejob, cnc chamber work and cnc porting?

Yes we can do all of the above. However I just recomend a good valvejob and some chamber work for that combo. I dont think you really need to cnc port the ports on that combo.

____________

Y2KZX12R

CompetitionCNC.com

|

osti33

Needs a job

Posts: 2973

|

posted July 18, 2007 12:47 PM

posted July 18, 2007 12:47 PM

quote:

Jim,

it looks like my int curve is missing a data point at .350.???

Optical dillusion???

On the unshrouding, gotta be careful with the offset cylinders...

In any event, thanks a million for testing both heads and posting them We will all learn something.

Ryan beats me at everything!

His wife even has a job!

Karl,

LOL. Your killing me here.

I have to keep my wife working. This is an expensive hobby.

|

osti33

Needs a job

Posts: 2973

|

posted July 18, 2007 12:53 PM

posted July 18, 2007 12:53 PM

quote:

As far as offset cylinders... It would be best to develop two diferent chambers, an inner and an outer. this way the shape is customized for the cylinder offset and the chamber isnt simply moved over. so there should be 3 chambers... a std location for std blocks and an inner and outer chamber for offset blocks.

Ryan, your BigBusa will have an offset cylinder block correct? I'll need that offset amount to shape your chambers as required for that BigBusa head coming up. That reminds me I've gotta get that plate fixture on order for the busa head. I'll be ready to work on that in august for ya.

Yes, the busa is going to have an offset block. I'm not sure off the top of my head how much they are offset but I can find out. I will let you know.

Thanks for doing all this flow testing for us Jim. This is great info.

|

Y2KZX12R

Needs a job

CompetitionCNC.com

Posts: 3762

|

posted July 18, 2007 02:16 PM

posted July 18, 2007 02:16 PM

Ok, thanks Ryan let me know. not knowing what bore and offset it is... but i was figuring that half of the added bore dia. would still be more than the offset. so in otherwords the chamber walls towards the center of the engine will still be bigger than the factory bore....

therefore not shrouding the chamber. So a symertical chamber will work fine.

We'll see...

____________

Y2KZX12R

CompetitionCNC.com

|

|

|

HOME

HOME ARTICLES

ARTICLES JOIN

JOIN GALLERY

GALLERY STORE

STORE SPONSORS

SPONSORS MARKETPLACE

MARKETPLACE CONTACT US

CONTACT US